clever protection for electronic components

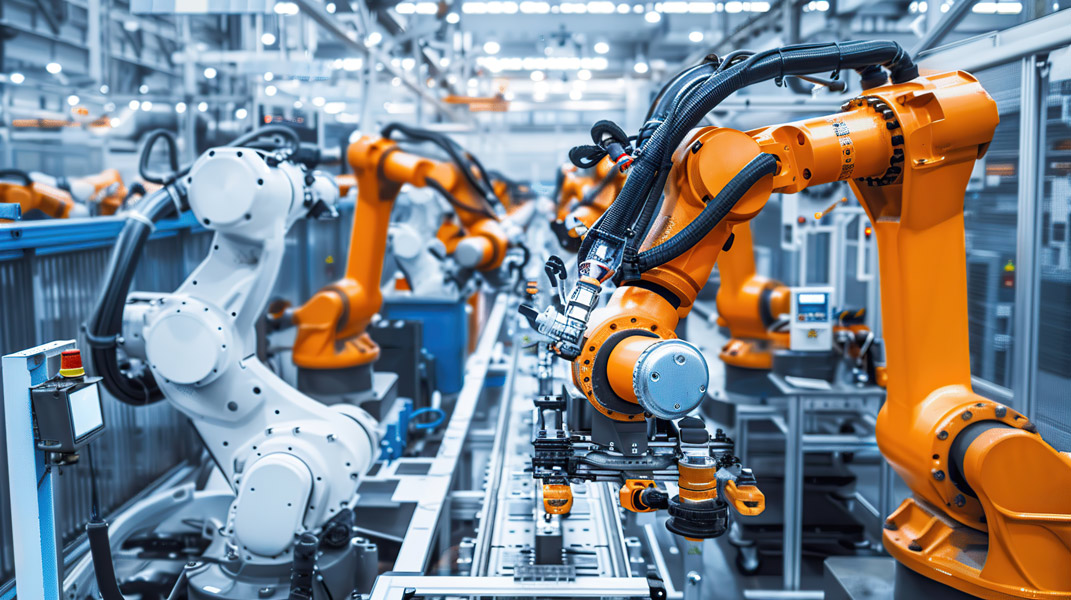

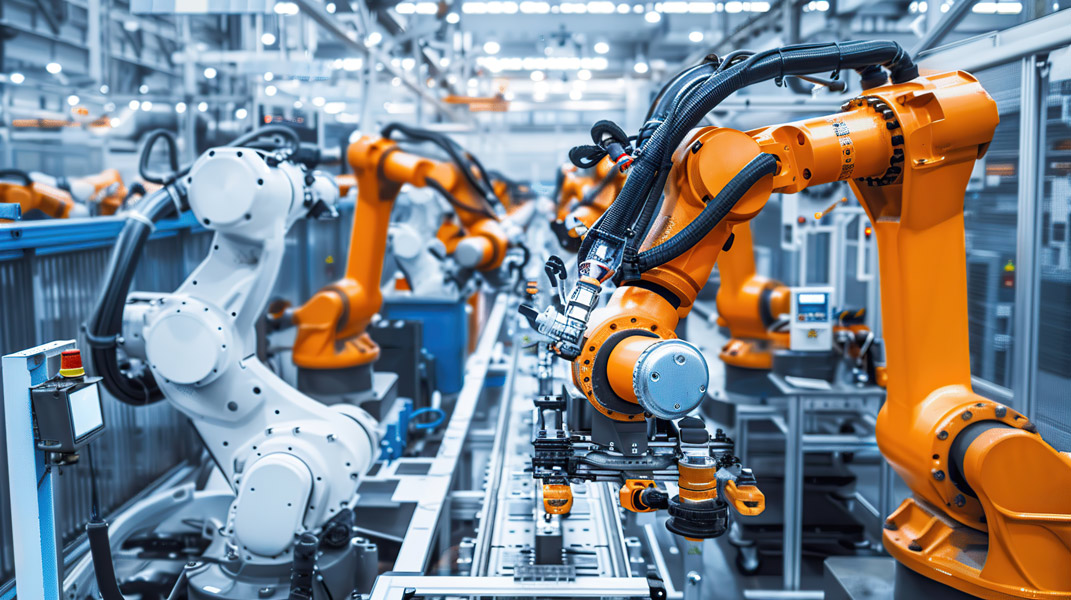

Electronic enclosures and empty enclosures from häwa protect electrical instruments and wiring from environmental influences. At häwa, you can customize electronic enclosures to your individual needs. For example, empty enclosures can also be used as encapsulation in control cabinets for robotic applications. Controls or electronic components can then be installed in these enclosures.

this is where they are used

Empty control cabinet enclosures are enclosures without any pre-installed electrical components or cabling. They are used in various industrial applications to protect, organize and isolate electrical equipment.

Empty control cabinet enclosures are used in the following areas:

- Industry

- Automation industry

- Mechanical engineering

- Building automation

- Traffic engineering

- Oil and gas industry

- Control engineering

Control cabinets enclosures

With häwa, you have the option of choosing between different materials for the enclosure types. We offer the materials stainless steel, sheet steel, plastic and aluminum. This allows you to choose the right material for your enclosure, depending on the requirements, for example, due to environmental influences.

häwa hygienic housings are always made of stainless steel, because stainless steel has a particularly smooth surface finish that can be cleaned hygienically. This makes the hygienic housings ideal for use in the food or clean room sector.

This is ensured by the Protection class of the control cabinet industrial enclosures

The protection classification for control cabinet enclosures provide comprehensive protection for electrical and electronic components in a range of industrial environments. These standards guarantee safety and reliability in accordance with internationally recognized norms. Protection classification always refer to the test conditions of the standard – they do not, however, provide any information about the application.

IP-Protection class (Ingress Protection)

IP Protection classification is defined by IEC 60529: The IP rating indicates the level of protection against the ingress of solid foreign bodies (first digit) and water or moisture (second digit) with two digits.

- Example IP66: Complete protection against dust and powerful water jets.

- Example IP69: Designed to provide protection against high-pressure/steam jet cleaning, ideal for demanding industrial cleaning processes.

However, the IEC 60529 standard does not provide any information about the installation location, external influences or conditions. If you wish to install your enclosure outdoors, additional measures such as corrosion protection or UV resistance are required.

UL approval

UL approvals stand for safety tests and standards: they confirm that a product has passed strict tests in terms of safety and reliability, in particular with regard to fire, electrical and mechanical risks. These standards apply to North America and Canada. You can recognize whether a product has a UL approval by the UL certification mark.

The importance of protection classification for industry

In general, approvals and markings for types of protection in the industrial sector provide the following information at a glance:

- Protection against environmental influences: Industrial enclosures with IP Protection classification provide reliable protection against physical and environmental influences such as dust, water, humidity and mechanical stress.

- Safety assurance: UL-approved enclosures ensure compliance with the highest safety standards, reduce risks and promote confidence in the application of the products.

- Compliance with international regulations: The combination of IP Protection classification and UL approval ensures that enclosures meet international and regional standards, which is essential for global trade and acceptance in different markets.

By taking IP Protection classification and UL approvals into account, manufacturers and users can be sure that their industrial enclosures will withstand the demanding conditions of industrial applications.

You can find more information about IP Protection classification here

for control cabinets and enclosures

The electrical components in the housings and control cabinets cause the interior to heat up due to their power loss. The increased housing temperature means that the electronics are no longer 100 percent comfortable and the required performance can no longer be fully provided.

Excessive temperatures can

- shorten the lifespan of technical components.

- Condensation can form.

- Predefined functions can no longer be properly executed and controlled.

häwa offers solutions to regulate the temperature inside enclosures and control cabinets. This can increase the lifespan of the electronics. Find out more about our filter fans, heat exchangers and cooling units.

Electronic housings from häwa – your advantages

With a well-thought-out design down to the last detail, häwa enclosures offer numerous advantages. In addition to a high degree of protection (IP66 or IP69), häwa also uses high-quality materials ranging from plastic (PC/ABS, polyester) to sheet steel and stainless steel.

Further advantages of häwa electronic enclosures:

Stability: The 26.5 mm frame provides exceptional torsional rigidity.

- Spaciousness: The well-designed mounting plate results in a high usable depth of: 16 mm.

- Security: High protection against environmental influences due to the IP55/IP66 or IP66/69 or Type 12 or Type 4X ratings.

- Innovation: The hinge of the electronic housings is concealed, but the door can still be opened up to 180°.

The häwa electronic housings also offer flexible mounting of attachments and built-in components as needed and numerous modification options to find the optimal solution for a variety of requirements.