What requirements must a cobot workstation fulfill?

Planning a cobot application is quite complex. It is not enough to just deal with the cobot and the appropriate tool. The robot frame can make a significant contribution to using the cobot as efficiently as possible in production. Learn more about planning.

- Development of cobot workstations

- Cobot applications in practice

- Specific design of cobot workstations

- Conclusion and advantages of cobot workstations

Solutions for cobot workstations To the X-frame model finder

Huge potential for the use of cobots in medium-sized companies

The high demand for cobots is certainly due to the fact that humans and robots work so well together, but also to the software, which is becoming more and more intuitive. Every manufacturing and production process is structured differently, and cobots perform a wide range of different tasks. That is why selecting a functional frame that is optimized for the respective requirements is crucial for implementing cobot applications. In this white paper, you will learn why the robot frame plays such a central role and what needs to be considered during the planning. After all, the aim during the planning is to optimize work processes and make them as efficient as possible. This is the only way to get the most out of your cobot application. What are the most common cobot applications? Which cobot workstation is right for my process? Integration of electrical and pneumatic components What are the business pitfalls to be aware of with frames?

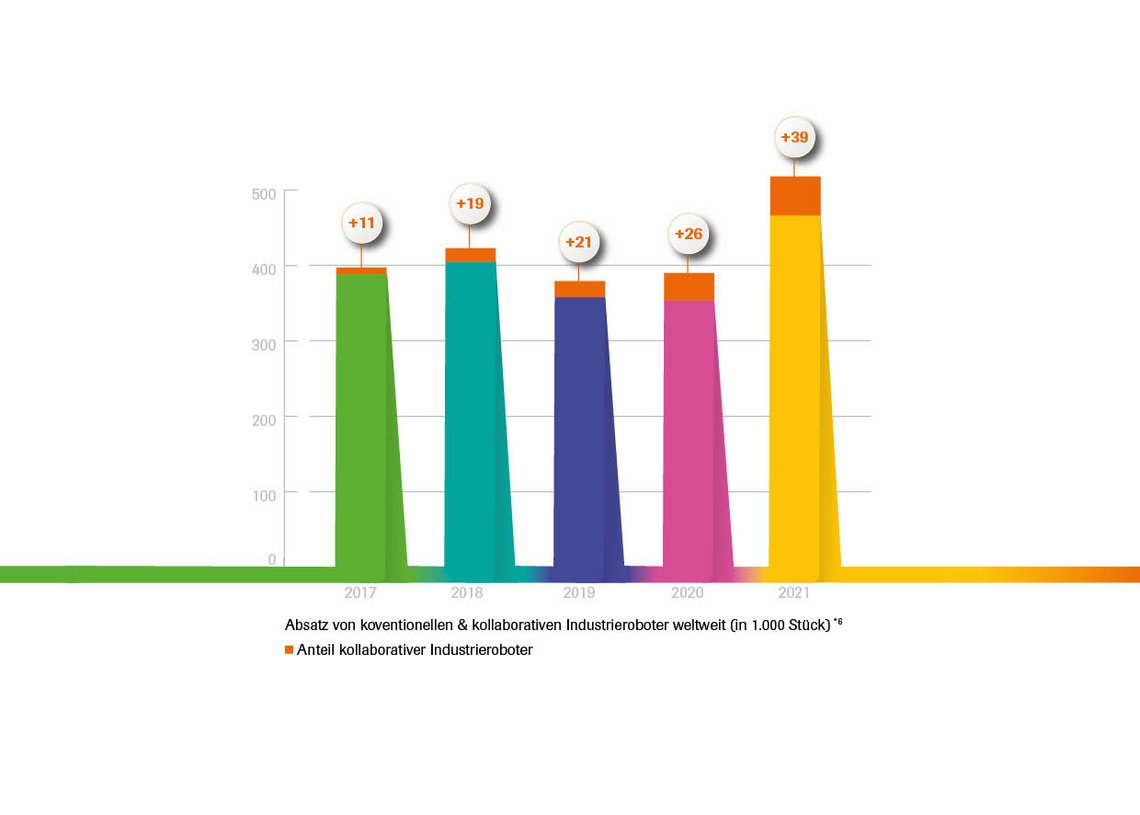

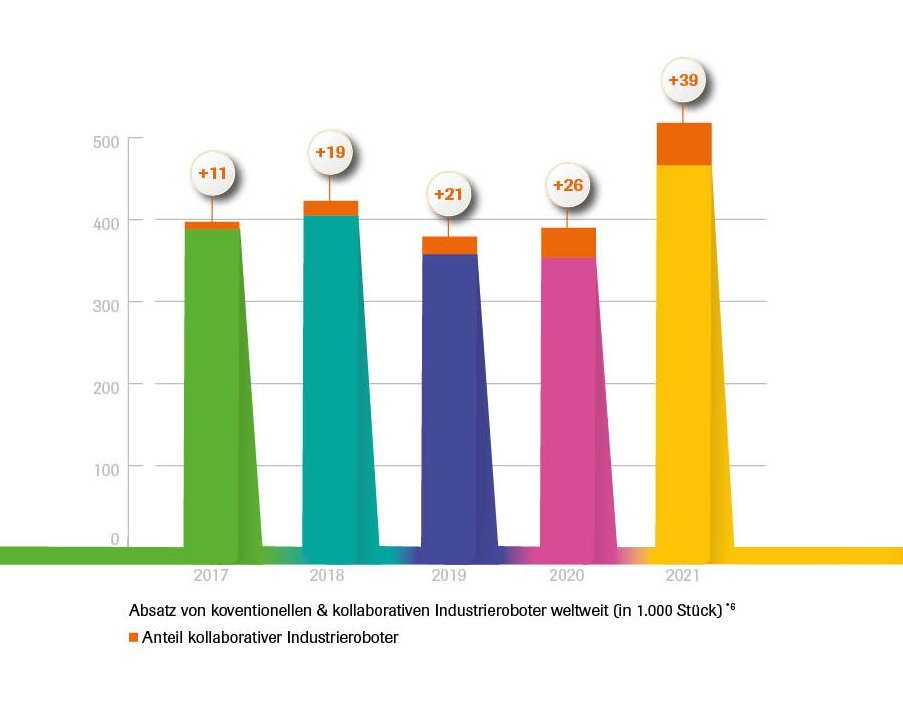

Graphic data - World Robotics 2022 | October 2022

free white paper Cobot workplaces as PDF

on the planning of cobot workstations, possible applications, planning tips for the automation of productions.

Register for the newsletter

The best switch cabinets and casings are not produced on an assembly line, but rather designed in close cooperation with our customers. Are you ready to begin? Then contact your personal häwa consultant.