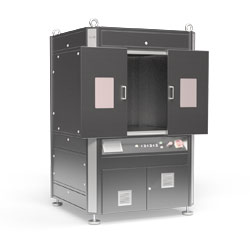

Complex large-scale plants and production lines with X-frame

When it comes to the design and realization of large systems, häwa can draw on a wealth of know-how accumulated over many years.

We have developed countless complex systems and production lines for our customers – even over long periods of time. The goal is always the same: to develop a comprehensive standard that can be used in different production stages. The modular design of the X-frame system is a great advantage for us. The basic frame designed for a production line can be quickly and easily modified with our system to create a customized special-purpose cell.

The biggest advantage is the integrated cable routing of the X-frame struts. In combination with our häwa control cabinets, highly complex electrical installations are possible in your production line. Cable separation and strut cross sections are aligned with the volume of the required lines. For advanced assembly, pre-lasered cable cutouts enable optimized cable routing even where it was not initially planned. This allows quick access to the cable-routing X-frame rack without tools.

The result for the customer: highly efficient, time-saving assembly of the individual system segments in-house.

The best ideas come from personal discussions, which is why we at häwa value personal contact and exchange. Your questions are best clarified in a conversation.

Contact now