Robotics is one of the leading disciplines of the 21st century.

Industry in particular is taking advantage of this to advance automation with highly developed robotic applications. The mostly sensitive industrial robots generate high torques and require protection by particularly stable robot cells. The X-frame machine frame can be used for a wide range of robotic applications. Hanging and standing robots are possible, as are lateral adaptations. Depending on the requirements, three different load stabilities are available for the robot cells. The X-frame can be individually constructed from these standardized designs. The three systems are compatible with each other, so that they can be optimally used in any area of a plant. This significantly reduces weight and costs. If required, high-quality, annealed and portal milling machine-processed welding frames can be integrated into the X-frame system. Even mobile cobot units, which are now frequently used in industry, are feasible with the X-frame for human/robot collaboration.

request project

Rotate, turn and zoom in on our häwa robotic cell.

How can X-frame machine frames and robotics be combined?

With the X-frame machine frame, häwa has developed a solution that can be used for a wide variety of robotic applications. There is a choice of different X-frame struts, depending on the load. The horizontal and vertical struts are manufactured in different levels of stability, which can be easily combined thanks to the modular design. The cable routing runs in the struts themselves. Individual adjustments are also possible here to avoid oversizing. With the X-frame machine frame, Häwa has developed a solution that can be used for a wide range of robot applications. There is a choice of different X-frame struts, depending on the load. The horizontal and vertical struts are available in various strengths and can be combined easily due to the modular design. Cables are routed inside the struts. Customizations are also possible here to avoid over-dimensioning.

Go to the X-frame model finder

The following X-frame braces are available from häwa

With their smaller cross-section, the specially developed X-frame Light struts allow a maximum access width on narrow systems.

X-frame braces are used for systems with weight loads of up to 1 ton. A special feature here is our vertical 90° corner braces. They are folded 13 times for maximum load.

We use our Pro-X struts made of 3 mm sheet steel to build machine frames for higher loads.

We have developed special robot struts for highly dynamic applications. With wall thicknesses of up to 13 mm, these can also withstand high torques and guarantee a high level of picking accuracy. We provide FEM calculations as proof of the quality of the systems.

For special requirements in terms of precision in an X-frame machine, häwa manufactures welding frames with the highest precision. Tube cross sections are adjusted and the frames can be annealed to prevent subsequent deformation. Milling in flat bed or portal milling machines and coating with the desired surface finish ensure a perfect result.

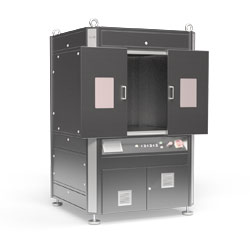

What is the structure of the protective housing for robots?

The X-frame can be individually constructed from standardized designs. The three load stabilities are compatible with each other, so that they can be optimally used in every area of a system to meet the requirements. This significantly reduces weight and costs. If required, high-quality, stress-relieved and portal milling machine-processed welded frames can be integrated into the X-frame system. The windows of the robot cells are usually made of polycarbonate (Makrolon). An optional FEM calculation ensures in advance that the required stability of the machine frame can be implemented – because safety and picking accuracy are of the utmost importance.

Solutions for various types of robots

Different robots require different solutions. häwa develops robotic cells for all standard robot types: Scara robots, delta pickers, articulated arm robots and linear drives. The robots can be mounted in a variety of ways, depending on the application and available space. Floor mounting is possible, as are lateral mounting on a wall, hanging mounting or horizontal mounting on a work plate – the X-frame machine frame can be customized to any application. Depending on the dynamic load, three different load ratings are available for the X-frame.

Häwa will support you in finding the optimal solution for your business. Robot cells are designed to meet your specific requirements. The X-frame modular system saves time and money during installation and design, while also providing maximum flexibility.

Examples of robotic cell applications

Robot cells are utilized in a wide range of industries. Each cell is customized to the industry and the robot application. häwa will work with you to develop a customized solution for your business.

Examples of robot cell applications:

- Complex robot enclosures

- Turning and sorting systems

- Robot assembly cells

- Robot cells in production lines

Solutions and products

The best ideas come from personal discussions, which is why we at häwa value personal contact and exchange. Your questions are best clarified in a conversation.

Contact now